Air Quality Management

Air Quality Management

Key Stakeholders : Government and Civil Society Organizations / Suppliers / Communities / Employees

Air Quality Management is a critical issue emphasized by several sectors due to air pollutants leading to air quality problems which affect the health and daily life of employees and people in the community. Moreover, it has a vast impact on the economy, mainly due to human activities. Although relevant legislation and measures have been imposed in many countries, such takes time and cooperation from all sectors to achieve efficient air quality management in a holistic manner.

Therefore, Mitr Phol Group prioritizes and maintains the air quality in all operational processes to meet standards and strictly complies with the law so that the business develops onwards with the good quality of life of the community and society.

Management Approach

To emphasize the significance of air quality control from the production process that may cause air pollution and potentially affect employees and surrounding communities, the company has developed a strategy, an air quality control and management plan, and guidelines for the development of air quality control systems for both within the factory and the surroundings, as well as measuring and monitoring air quality regularly to ensure that the air quality is in accordance with the law provision. Mitr Phol also applies advanced and environment-friendly innovations and technologies to business operations and prevents air pollution through compelling air quality management.

Significant Changes

1. Air Pollutant Impact Assessment Project based on AERMOD Simulation for 4 Consecutive Years

Panel Plus Co., Ltd. a subsidairies of Mitr Phol Group has applied the AERMOD Simulation to assess air pollutant dispersion by using the meteorological data and the results of air quality measured at the ventilation stacks. After applying the principle, the Company has developed in Wet Electrostatic precipitator (WESP) at Panel Plus Co., Ltd. Songkhla province. The system can vacuum dust into the system that reduces direct impact, and the indirect impact which the dust is returned in the production process to use as raw material.

In addition, the Company continues the workshop for executives and employees of all levels to raise awareness, understand factors for pollution dispersion and pollution control. The AERMOD simulation is applied as in integral part of the Environmental Impact Assessment Report (EIA) and further brought to analysis and determine measures that control and prevent pollutants as specified in EIA and the irrelevant ones. There is the compliance monitoring within Mitr Phol Group.

2. Air Pollutant Prevention

Mitr Phol Group's operation to prevent air pollutant is divided into 3 categories which are air pollutant prevention at the sources, air pollutant through the passage, air pollutant prevention at the community.

Prevention at the Source of Emission

- The combustion in a boiler is controlled by using proper fuel and combustion factors to reduce NOx, SOx, CO, TSP and enhance complete combustion.

- Install the Wet Scrubber with the efficient capacity to control dust by 80%. Gradually, the Company will apply the modern Electrostatic Precipitator, which can control emission by 99%, to trap dust from the combustion in biomass power generation.

- Dust Control in wood substitute production which the Company has installed air treatment with a Multicyclone system, having emission control capacity by 80%and install additional water spray at the end of stack of the multi-cyclone air treatment system.

- Within the production building, the Company installs dust vacuum and collection system in the wood substitute production process. Vacuum vehicles are running around the disc wood yard, bringing back the dust as a fuel for a combustion furnace in the production process.

- Inspect quality at the ventilation stacks to ensure compliance with the laws and environmental impact assessment report (EIA).

- Continuously inspect the smoke opacity emitted from the stacks based on Ringelmann Smoke Chart as a monitoring procedure to control the combustion efficiency.

- Closely monitoring to control combustion efficiency.

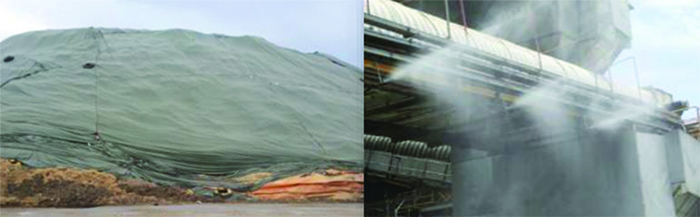

- Cover materials and fuel storage management, for instance, bagasse.

Prevention of the Passage

Control dust from bagasse conveyor belt into the biomass power plant; regularly inspect for leakage on the belt; install cover for the conveyor belt and use the mobile belt to transport bagasse. The conveyor belt contains bagasse spreader to maintain bagasse on the belt, water spray and bagasse dispersion prevention equipment with adjustable height.

- Plant pine trees as a wall to block dust from the bagasse pile and install high mesh wall around the bagasse piles.

- Install wind break to divert wind direction toward bagasse pile.

- Use water mist sprayer and big gun to spray water the bridgehead and the mesh.

- Install pipes for dropping bagasse to prevent dispersion.

- Install wind shock to monitor wind direction at the bagasse and sugarcane leaf piles.

- Regularly remove accumulated dust on the roof, buildings, fuel conveying systems to minimize dust dispersion outside the premise.

- Install the mesh at the air passage or vent outside the bagasse and sugarcane leaf pile.

- During the sugarcane crushing season, spray water on the roads within the factories and around the neighbouring communities to minimize dust effect on traffic.

- Implement dust prevention for the disc wood yard (raw material of the wood substitute production) which includes mesh, water spraying around the material piles, soil bank and tree lines.

Prevention at the Communities

- Measure air quality around the factory under EIA measures. For instance, small particles not exceed 2.5 micron (PM 2.5), large particles with diameter 100 micron and less (TSP).

- Survey dust impact on the community to bring the result for analysis and seek for solution.

- Install monitoring sets which include white cloths, black cloths in the factories and communities to assess dust volume for further analysis.

|

|

|

Dust management at the bagasse storage yard, for instance, covering bagasse piles, spraying the pile with water to prevent dust dispersion, using the mesh and tree lines around the bagasse piles |